Top Guidelines Of Replacement Glazing Panels

Table of ContentsAll about Concrete Spandrel PanelOur Aluminum Spandrel Panel PDFsOur Replacement Double Pane Glass Panels Statements

Blast lots Unintentional explosions and also terrorist hazards have prompted boosted issue for the fragility of a curtain wall surface system in regard to blast lots (replacement double pane glass panels). The battle of the Alfred P. Murrah Federal Building in Oklahoma City, Oklahoma, has spawned much of the current research as well as mandates in relation to building reaction to blast tons.

and also all UNITED STATE embassies improved foreign soil has to have some arrangement for resistance to bomb blasts. Since the curtain wall is at the outside of the structure, it comes to be the initial line of protection in a bomb assault. As such, blast immune drape wall surfaces are developed to endure such pressures without compromising the interior of the structure to secure its passengers. aluminum spandrel panel.

Blast immune glazing contains laminated glass, which is indicated to break but not divide from the mullions. Comparable innovation is used in cyclone- susceptible locations for influence protection from wind-borne particles. Air infiltration is the air which travels through the drape wall surface from the outside to the inside of the structure.

The American Architectural Manufacturers Association (AAMA) is a market profession group in the UNITED STATE that has established volunteer specs relating to acceptable levels of air infiltration through a curtain wall (replacement double glazing panels cost). Water infiltration is defined as water passing from the outside of the structure to the interior of the curtain wall surface system.

How Aluminum Spandrel Panel can Save You Time, Stress, and Money.

Regulated water penetration is defined as water that penetrates beyond the internal most upright airplane of the test specimen, but has a designed means of drain back to the exterior. AAMA Voluntary Specifications permit regulated water penetration while the underlying ASTM E1105 test technique would specify such water penetration as a failure.

This established imitates a wind driven rain event on the drape wall surface to look for area efficiency of the item as well as of the installation. Area top quality control as well as assurance checks for water infiltration has become the standard as home builders and also installers apply such quality programs to assist lower the variety of water damages lawsuits matches versus their job - opaque glazing panels.

Deflection in mullions is controlled by different forms and depths of curtain wall participants. The depth of a provided drape wall surface system is generally regulated by the location minute of inertia called for to keep deflection limits under the spec. An additional way to limit deflections in a given area is to include steel reinforcement to the within tube of the mullion.

Excitement About Replacement Double Glazed Glass Panels

Stamina (or optimal usable anxiety) available to a specific product is not associated with its product rigidity (the product home regulating deflection); it is a separate requirement in curtain wall surface layout and analysis. This usually influences the selection of products as well as sizes for style of the system. The permitted flexing stamina for certain aluminum alloys, such as those usually made use of in curtain wall framing, approaches the allowed bending strength of steel alloys utilized in structure construction.

This converts right into high heat loss with light weight aluminum curtain wall surface mullions. There are numerous methods to make up for this warmth loss, one of the most common method being the addition of thermal breaks. are barriers in between exterior steel as well as interior steel, generally constructed from polyvinyl chloride (PVC). These breaks provide a substantial decline in the thermal conductivity of the curtain wall surface.

Thermal conductivity of the drape wall surface system is very important because of warmth loss through the wall, which affects the home heating and cooling expenses of the structure. On an improperly doing drape wall surface, condensation may develop on the inside of the mullions. This might cause damage to nearby indoor trim and also walls.

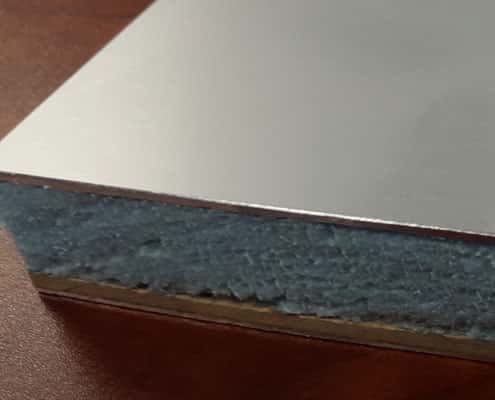

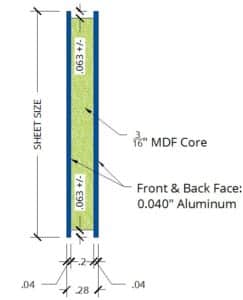

Infill describes the large panels that are put into the curtain wall surface in between mullions. Infills are normally glass however might be composed of virtually any kind of exterior structure aspect. Some common infills include metal panels, louvers, as well as solar visit here panels. Without a doubt the most common glazing kind, glass can be of a nearly infinite mix of color, density, as well as opacity.